New building coming Fall 2024

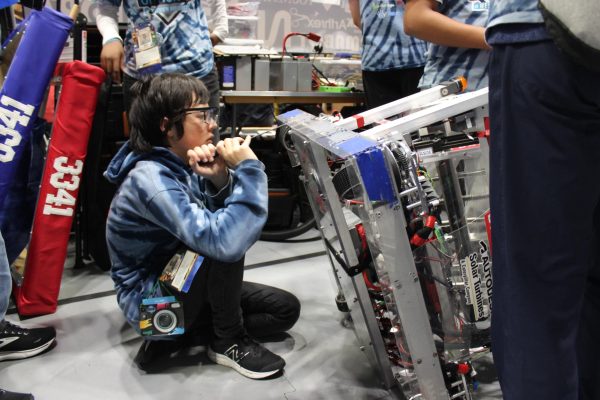

The building will feature engineering, robotics, and collaborative spaces.

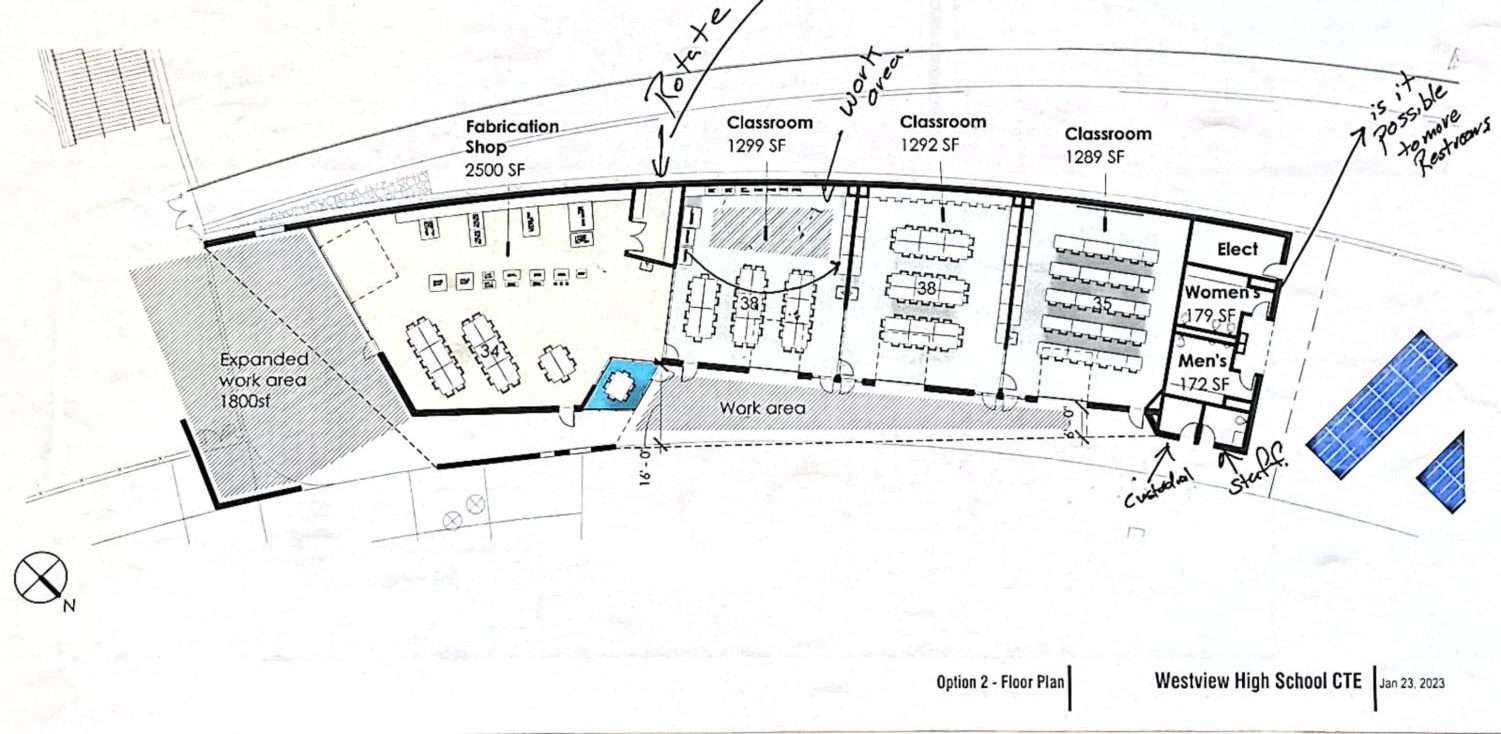

Construction of a new building with expanded engineering and robotics facilities will begin later this year and is slated to finish in fall of 2024. The building will be located behind the D-building, where the current storage containers are. The space, a total of approximately 8,500 square feet, will include three classrooms, a fabrication shop, and two outdoor work areas.

Rheia Alschbach, the Assistant Director of Planning in PUSD, said that since the boundaries for attending Westview include multiple Mello-Roos districts, PUSD was able to allocate funds from Mello-Roos taxes to build the additional classrooms.

Although the final cost will be determined after the design and project bidding is complete, the budget for the project is $7.5 million.

Principal Ernie Remillard said that the initial conversation for the construction started approximately a year ago, with former Principal Tina Ziegler and former Assistant Principal Darcel Glover.

“We saw a need for not only our engineering, but also our robotics program, which has grown substantially over time,” Remillard said. “In robotics, students have to move parts just to access equipment and supplies. So if it’s downpouring, how do they practice? It’s not really a conducive current environment [to work in].”

Physics teacher Dawn Hester was involved in developing the engineering Career Technical Education pathway at Westview—the courses that will be taught in the new building. Currently, robotics and engineering courses are being held in the trailers located near the back of the school.

“It’s a challenge to be in a space without a true fabrication shop,” Hester said. “We’re making do with everything that we have. We’re teaching engineering and robotics classes in a portable [trailer]. The floor won’t support heavy shop equipment like CNC routers and mills. There is limited electrical supply and space for large robotics projects. The standard-sized doors limit the workflow of projects and use of large equipment.”

In order to accommodate for the trailers’ limited functionality, the engineering classes pull out their equipment and meet outside, spreading out in different classrooms.

“We end up using the portable [trailers] as storage, so it’s been limiting,” Hester said. “When we meet outside and pull everything out, it takes a lot of time and it’s also not the safest way. It’s not the best for student learning. We run extension cords out through doors and there’s also poor lighting when we work at night.”

The fabrication space in the new building will house various engineering tools and heavy equipment, as well as 3D printers.

“One of the things the new building will have is an indoor-outdoor area, like a gazebo,” Remillard said. “It could be a practice area for robotics, but it could also serve as a place that an English teacher could bring students to listen to a guest speaker, for example. We really want it to be a shared space throughout our campus.”

Two unique features of the new building are see-through glass walls separating classrooms and garage doors instead of typical doorways. The glass walls will allow teachers like Hester to be able to monitor the various projects students are executing throughout multiple classrooms.

Beyond that, Remillard said another goal with the project is not only to provide spaces for robotics and engineering, but to build classrooms that can be utilized for a variety of purposes.

“When we initially start thinking about buildings on our campus, we’re not really thinking about them as lifetime engineering rooms,” Remillard said. “Even if an English classroom started out as an English classroom, it needs to be able to shift to a math classroom, or science, or world language. So we’re really looking at the spaces that are initially established to be in the engineering world, but over time, we’re being mindful that they could be used for anything another 10-15 years down the road.”

The process initially started with walk-throughs for architects in July 2022 to view the campus. After a follow-up meeting, the classrooms were each designed to be approximately 900 to 950 square feet, the size of a standard classroom.

“We were concerned about the size of the rooms,” Remillard said. “A science classroom runs about 1,300 square feet, and we needed more of a standard science classroom size than a standard English classroom sized-space. So over time, [architects] really started to understand what our priorities as a school were with these different rooms.”

The initially proposed six classrooms were cut down to four, three of which will be about 1,300 square feet. The fourth, the fabrication shop, will be approximately 2,500 square feet. Similarly, the fabrication shop was initially a maker-space, one more geared towards arts and crafts. Later on, the maker-space was eventually transformed to a larger machine-shop.

“The square footage we’re working with doesn’t change,” Remillard said. “We did have the flexibility for certain room size changes and the number of rooms, but we couldn’t expand out on to the solar panels or into the pool area off the backside.”

Ultimately, Hester said she is excited that the new building is designed to safely teach robotics and engineering classes and to promote both collaboration and innovation in these project-based classes.

“It’s really exciting to be a part of designing and building a collaborative space to build and teach these classes that focus on student learning,” Hester said. “Collaboration in engineering is powerful. You’ve got software development on one side, people fabricating on another side, and people working on electronics, laser-cutting, soldering, and 3D printing. [We are bringing all that together] while having visibility between those work areas. There’s intentional collaborative space that has gone into the design that makes it really exciting to be a part of this project.”

![Kamila Nava (11) [right] and Alexi Stysis (11) run at Torrey Pines State Beach, April 27. Nava enjoys going for runs outdoors and tries to run in nature as frequently as possible.](https://wvnexus.org/wp-content/uploads/2024/05/DSCF2398-e1714686258569-400x600.jpg)