The International Genetically Engineered Machine competition (iGEM) club has been attempting to genetically engineer a bacteria that can quickly degrade polyhydroxybutyrate (PHB) plastics, which are biodegradable. They’ve been working in a lab for the past six months on Project PHoeBe for this year’s iGEM competition, where presentation of projects to the judges will begin, Oct. 28. PHB is more sustainable and environmentally friendly than the widely used non-biodegradable plastics, but there is currently no way to efficiently recycle it.

Currently, with non-biodegradable plastics, recycling them over and over again results in a decrease and weakening in quality. The repetitive cycle of melting and reforming the plastic contributes to microplastic pollution as the weakened items are more easily broken down into smaller pieces after use. Additionally, with the current way of recycling, plastics get downcycled, leading to the over-recycled objects to become worse in function and quality.

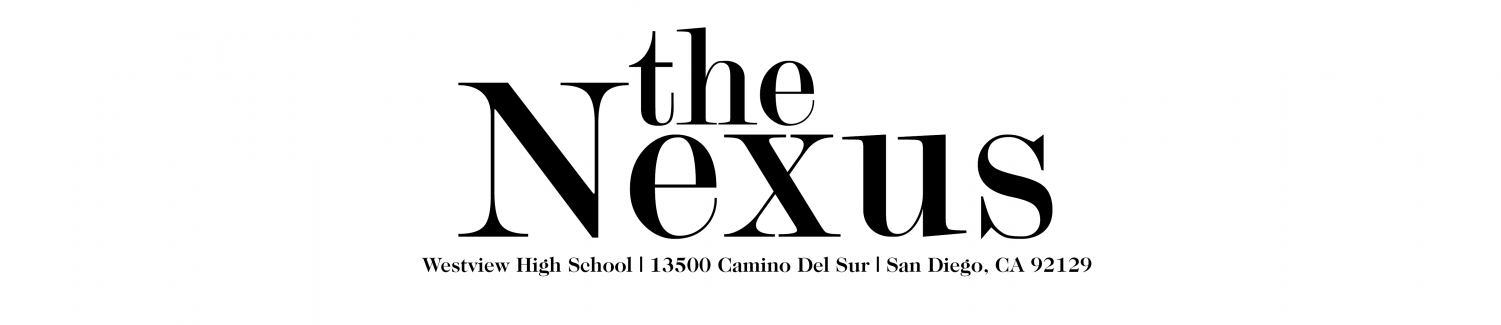

The team’s Wet Lab division is responsible for completing the hands-on experimentation inside a lab with bacteria and their different genes of interest, conducting iterations under controlled conditions to ensure accuracy in their results. These experiments are to construct plasmids, tiny, circular DNA molecules that are separate from chromosomal DNA, that will contain the genes of interest.

By engineering a bacteria that can successfully degrade PHB plastics at a faster rate, Serena Tran (12), a Wet Lab Co-Lead and Outreach Lead, said she hopes to help contribute to a decrease in plastic pollution through easier recycling of PHB.

“Plastic pollution has been the problem that we’ve been concerned about for years,” Tran said. “Nowadays, people are trying to advocate for less use of non-biodegradable [plastics] and more use of biodegradable ones.”

Through degradation, the quality of PHB plastics won’t deteriorate nearly as quickly over time because the process of chemically breaking it down into small building-block molecules and then resynthesizing them back up into PHB again keeps the plastics more intact.

The Wet Lab team of 14 members is utilizing two genes, dehydrogenase and depolymerase, and combining them into a plasmid to produce a new bacterial strain containing the plasmid with both genes.

“We’re trying to use these two genes to try out the complete biodegradation pathway process of PHB,” Tran said. “We’re trying to put these genes into this marine bacteria called Alteromonas, and we’re trying to see if this marine bacteria, with our two genes, can actually degrade PHB better than the natural, wild-type, Alteromonas already can.”

During the process of engineering this bacteria, the team ran into some problems with creating the final stage of the plasmids. To do so, the team needed to combine two level-one plasmids, each with one of the two genes, into the final level-two plasmid that includes both genes. President David He (12) said the process of trial and error with producing the bacterium brought some setbacks as the competition drew near.

“We ran into a really big problem when we were designing plasmids,” He said. “We want to design levels of plasmids, and the highest tier is level-two. This is the plasmid we want to create and engineer into bacterium, but the reactions that we were making were failing. We attempted this many, many times, and we tried many different parts and ways to create the level-two plasmid. We just ran many iterations, and none of [them] worked, so unfortunately, we ended up having to scrap that for now and just stick with a level-one plasmid and engineer it.”

On the other hand, the Dry Lab team, consisting of 11 members and co-led by Thomas Tong (12), is responsible for taking the enzyme sequence and utilizing AI software to generate models, piecing together different types of bonds and interactions from the sequence. This division focuses on the computational aspect of the competition, honing in on biological informatics to digitally experiment with the bacterium and enzymes.

The Dry Lab team conducted docking studies, which allowed them to see how well the plastic binds to the degraded enzyme. Without a mentor, they had to figure out their own approaches and solutions to the project this year.

“We started doing some docking, but because we don’t have a mentor this year for Dry Lab and I’m not as experienced as I should be, we did run into some experimental design errors,” Tong said. “For example, we didn’t include a negative or positive control, and I realized that our docking would be better if we actually did some molecular dynamic simulations first to make sure our protein is simulated in an environment where it should be, [so] it’s more realistic.”

Being thrown into the research process without the support of a Dry Lab mentor was completely foreign to Tong.

“We taught ourselves the concepts that we didn’t really understand, and then we tried to dumb it down to teach our team members all these things that we learned,” Tong said. “It was pretty difficult, we didn’t know where to start, we made a lot of mistakes, we had a lot of roadblocks, it was a pretty challenging jump, but we’re getting through it.”

As the 2025 iGEM competition nears, the members of the team are concentrating on completing the final touches to Project PHoeBe. He said he hopes to spread knowledge in biology, informatics, and team research at Westview and help students gain access to opportunities that are otherwise scarcely offered to high schoolers.

“One of the big points of having an iGEM club on campus is to introduce a lot of students into studying biology,” He said. “A lot of high-school students don’t get the opportunity to try out research, especially with genetic engineering and biology, and iGEM opens up a lot of opportunities for people to do so if they wish. A lot of avenues will not be opened without iGEM, so I’m hoping a lot of people get experience and even possibly decide if they want to pursue [biology] as a career in the future.”